With the adaptation to the continuous changes in the glass interlayer and pursuing higher energy efficiency, the production of laminated glass process has also developed. Manufacturing technologies such as vacuum lamination and rapid fusion radio frequency lamination have also continued to emerge.

Introduction

The main components of laminated glass are processed through autoclave, intermittent or continuous vacuum lamination, on-site casting, and rapid fusion radio frequency lamination technology. The laminated glass process has changed the brittle and hard characteristics of traditional glass and is widely used in the isolation of car windshields, transparent windows, business halls, etc.

Laminated glass avoids injuries and cuts that may occur when traditional glass breaks. This kind of interlayer in the middle of the glass can aggregate the glass fragments when the glass is damaged, thereby reducing the harm caused by the glass fragments to the human body. This kind of laminated glass can also be used to resist attacks from impact objects and penetrating objects. This provides features such as safety, sound insulation, and solar energy control. So there are also characteristics of green products.

In the early days of laminated glass, cellulose nitrate, and cellulose acetate were mainly used as interlayers. Since 1938, laminated glass has been used for automobile windshields by DUPONT Company, and it has been widely used, which also opened the prelude to the laminated glass industry.

Laminated Glass Process

PVB is widely used in laminated glass. It is the earliest resin used in laminated glass panels. The laminated glass process and autoclave lamination work is the process of manufacturing this part, which is also a key part of the laminated glass manufacturing process of laminated glass manufacturers.

The application of this material still occupies an important position in the industry today. The laminated glass process mainly includes the selection and storage of PVB film, the environment of the laminating room, the cleanliness of the glass sheets, the laminating method, preheating and pressing, and the operation technology of the glass in the autoclave, etc.

Among these production processes, the lamination process, the glass preheating and pre-pressing process, and glass operation in the autoclave are the more difficult processes in the laminated production process. For this Analysis and research on several aspects are key to ensuring the quality of laminated glass. Therefore, we will conduct an in-depth discussion on the production process of this part.

Glass Lamination Process

Firstly, choose a PVB film suitable for the width of the glass, and keep the film clean. Avoid directly touching the film and glass with your hands.

Flatten the PVB film naturally without stretching it, and align the inside and outside of the glass. The film should not be uneven. Check whether the reserved marks overlap, and then cut off the excess film. When performing the cutting operation, keep the blade tilted and leave 0.5mm to 2mm of film on the edge of the combined film. In order to avoid Film shrinkage causes shrinkage.

After lamination of the PVB film and glass, put on the vacuum rubber ring and check the sealing strip.

The tension around the glass should be uniform. Then cold-pump the glass to remove the air between the two pieces of glass panels. The cold-pumping time should not be short in 5 minutes.

Glass Pre-heating And Pre-pressing Process

The glass panels are clamped with PVB film, and after the air is evacuated, the combined glass is pre-heated and pre-pressed.

There are three types of equipment for preheating and prepressing operations.

One is the pre-heating and pre-pressing box. Because of its simple equipment, small investment, and low energy consumption, it is favored by many manufacturers. However, the disadvantage of the preheating and pre-pressing box is that it is low in efficiency and cannot be adapted to industrial production.

Transmission-type vertical and horizontal preheating and pressing machines are more efficient in production and are suitable for large-scale production. The difference between them is that when placing the glass to complete the pre-heating and pre-pressing work, the glass is placed vertically and horizontally. When the vertical pre-heating and pre-pressing machine evacuates the glass panels, it has little impact on the curvature of the glass. When the horizontal preheating hot press machine evacuates the glass, since the glass lies flat, the curvature of the glass is affected by its own gravity and vacuum pressure.

Therefore, the horizontal pre-heating and pre-pressing machine is more suitable for the production of large-size glass.

The Process Of Glass In The Autoclave

The autoclave is a laminated glass machine, also, the manufacturing process in the autoclave is the last process in the production of laminated glass.

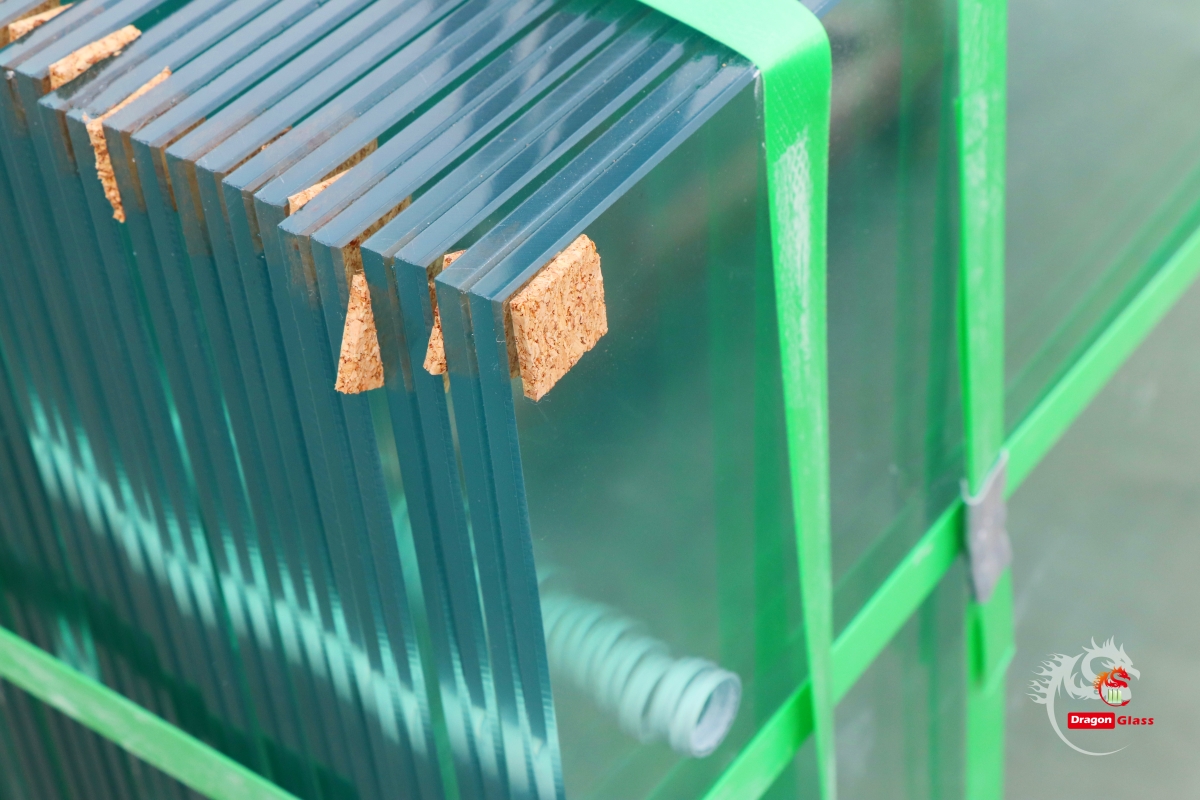

In order to make the PVB film and the glass panels better laminated together, the glass that has been pre-heated and pre-pressed must be treated with constant temperature and high pressure before it can be used. Constant temperature and high-pressure treatment should be performed in an autoclave. First, isolate the semi-finished products of laminated glass that are bonded together, put them on a special glass shelf for the autoclave, and make them firm, then close the autoclave door tightly, and the autoclave is pressurized and inflated.

When the air pressure in the laminated glass machine reaches about 0.75MPa, stop inflating the autoclave. This is because the edges of the laminated glass are not firmly bonded, in order to allow the space in the middle of the glass interlayer to overflow under the action of pressure and prevent air from entering the interlayer from the edge.

When the temperature in the laminated glass machine reaches about 130°C, stop heating immediately and maintain this temperature. At this time, the glass can be bonded, and the autoclave is pressurized a second time. Since the glass has reached the bonding temperature, air will not enter the interlayer during this pressurization. When the pressure reaches 1.2MPa, stop pressurizing and Keep the pressure balanced. After 1h to 1.5h, lower the temperature in the kettle to 50°C, start to exhaust and depressurize the kettle until the air is completely discharged, open the autoclave door, and push out the glass.

At this point in the laminated glass process, there is still the finishing work, which is to inspect the glass piece by piece and trim the qualified products. Cut off the excess PVB film around it, select and repair the glass containing bubbles and degumming, and re-enter the autoclave to pressurize and heat.

With the continuous improvement of production technology, most autoclaves have automatic control functions. In actual operations, laminated glass is processed according to its own characteristics and actual conditions.

Shenzhen Dragon Glass is a world leader in laminated glass manufacturing. We provide customized services to give you the best solution that accommodates all your needs, from iconic architectural projects that push the boundaries of glass technology, to economical home glass, guaranteeing good quality products and excellent customer service.

Dedicating themselves to making each piece of glass perfect! That is the reason our company keeps growing bigger and bigger. Contact us, and let’s make wonderful glass projects together.