elegant and safe glass solution

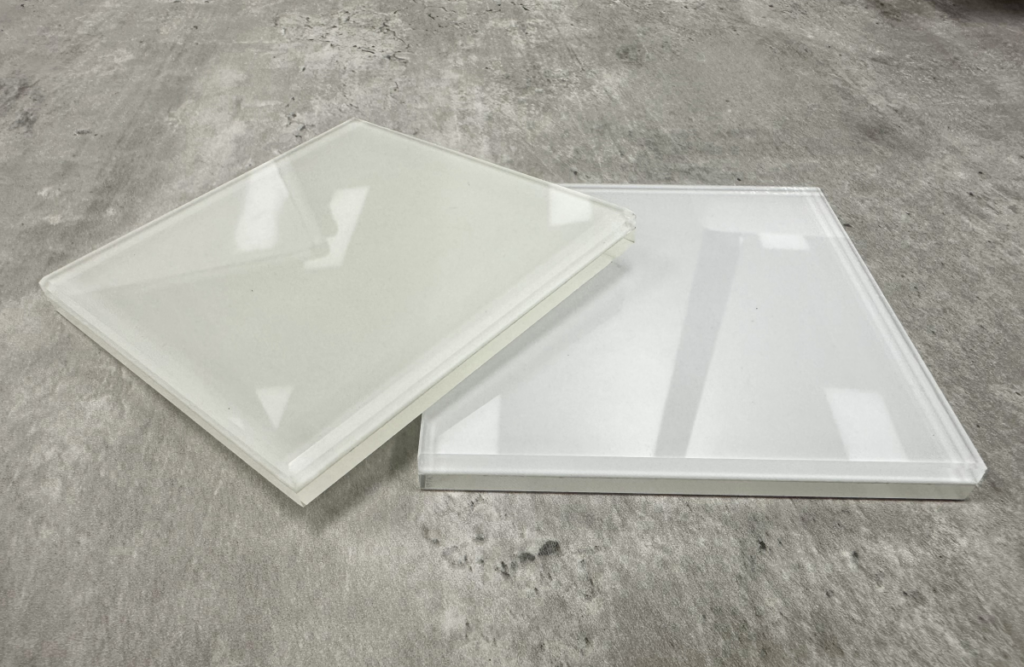

Hot Bending Laminated Glass

Hot bend laminated glass is laminated annealed glass that is heated and softened in a mold by the flat glass and then laminated, it’s the safety glass. In hot bending, the manufacturer uses molds, once the kiln reaches the desired temperature – about 650 degrees C – the molecules in the glass begin to speed up and it begins to melt and bend, bending can be solely based on gravity. And then, laminated it. Bending laminated technology allows producers to create a wider range of shapes, for instance, a tighter radius and non-cylindrical shapes.

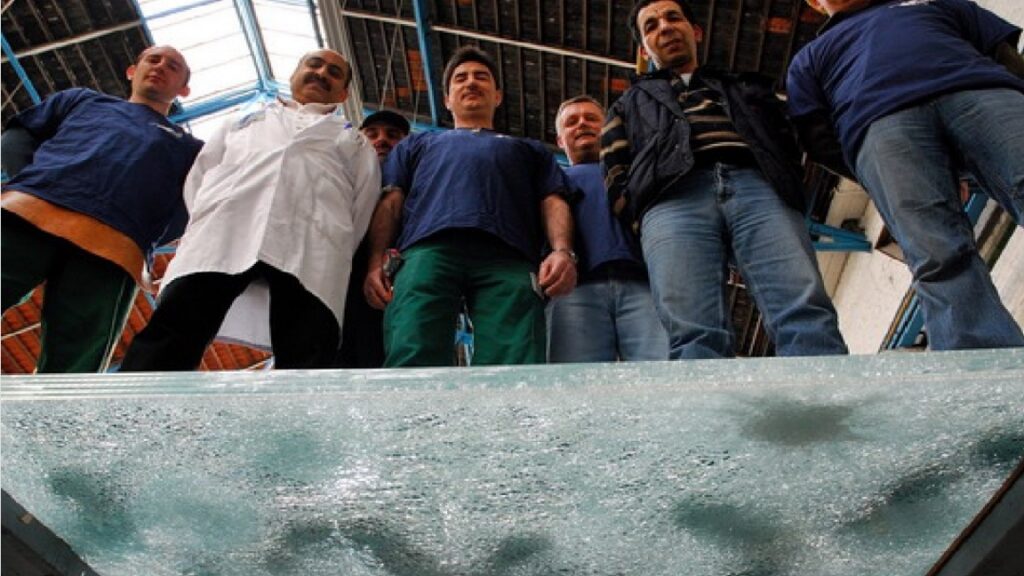

30 Years+ Of Experience In Laminated Glass Production

Shenzhen Dragon Glass offers a vast selection of hot bending laminated glass options to meet your specific requirements.

Size range

Oversize Glass Configurations available up to 2750mm X 6200mm

Interlayer Film Thickness Options

0.38mm, 0.76mm, 1.14mm, 1.52mm, 2.28mm, 3.04mm, etc.

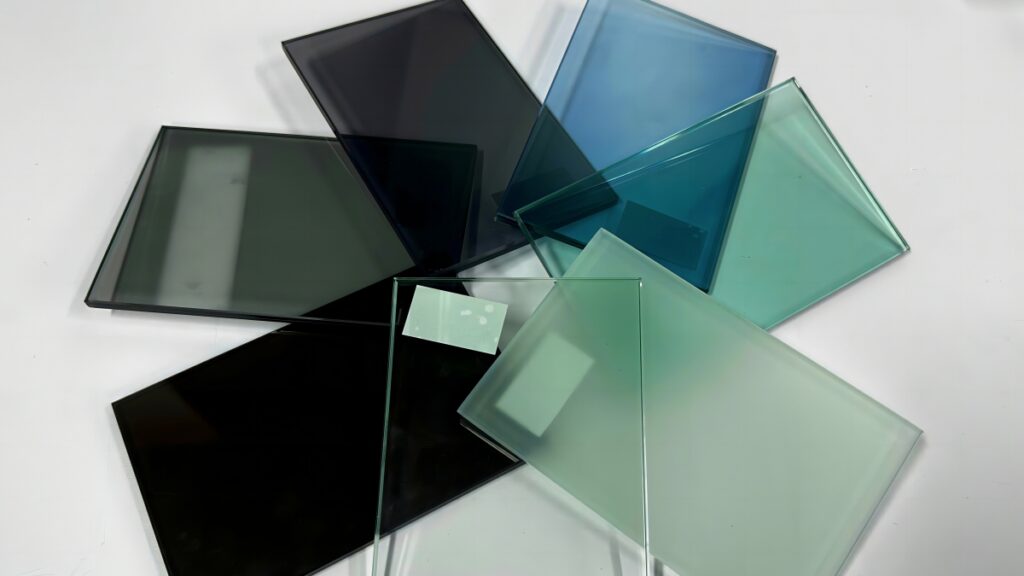

Interlayer Film Colors Options

Clear, Ultra Clear, Green, Grey, Blue, Yellow, Red, Purple, Orange, etc.

Glass Thickness Options

Single glass panel thickness: 4mm~19mm, up to 7 layers.

Glass Types Options

Tinted glass, Energy-saving glass, Decorative glass, Curved glass, Insulated glass, etc

Shape Options

Variety of styles, as you wish.

Components and Enhancements

Edgework

Notches & Cutouts

Holes

Glass Options

Interlayer Film Options

Samples & Mockup

everything you may want to know about Hot bending laminated glass

Hot bending laminated glass products have a variety of styles; curved tempered laminated glass has a single style, which is only suitable for curved arcs with a radius of more than 420mm.

Hot bending laminated glass is produced by permanently bonding two pieces of glass together with an interlayer or resin. Several types of film and glass may be applied in the process, to obtain different characteristics for the structures – according to the purpose of use.

Yes, all the laminated glass product is safety glass.

The surface of the hot bending laminated glass is smooth and there is no optical distortion; the curved tempered laminated glass has a little wind spots and “broken shadows”.

Yes, hot bending glass products can be processed by cutting, drilling holes, etc.; curved tempered glass has no secondary processing capability.

Bending glass involves heating up to 650 degrees Celsius. The high temperature is sufficient to soften the glass to a condition where you can bend it. Using gravity or mechanical pressure we can pull the glass into the desired shape.